Experimental Study on Building Element Subjected to Marine Concrete - Juniper Publishers

Juniper Publishers- Open Access Journal of Environmental Sciences & Natural Resources

Experimental Study on Building Element Subjected to Marine Concrete

Authored by Manikandan R

Abstract

Generally composite structure means two or more materials combined together and act as a monolithic structure by means of connecting them by some connectors. Steel-concrete composite plays a major role in construction industry. Composite slabs are composed of steel decks and concrete. There should be a connection between steel deck and concrete to have monolithic action. Cold formed steel can be used as profile deck so that weight of structure reduces. During the application of load, flexural, vertical shear and longitudinal shear failure may occur. Among this, longitudinal shear failure plays a vital role. The strength of the composite slab mainly based on longitudinal shear bond mechanism between steel deck and concrete. The longitudinal shear strength depends on thickness of profile deck, shape and inclination of deck and embossment and dimples pattern in the deck. But many of the designs are arrived in the deck slab Design. So this project focuses on concrete layer that present above to the deck. Normally all researchers focus only on deck slab but they use concrete as it is normal concrete & light weight concrete. Due to the usage of light weight concrete, the concrete easily fail under impact. So this project aims to adopt marine concrete that is replacement of river sand by sea sand.

Keywords: Marine; Light Weight; Deck Slab; Shear

Introduction

Composite Steel-Concrete Structures are used widely in modern bridge and building construction. A composite member is formed when a steel component, such as an I-beam, is attached to a concrete component, such as a floor slab or bridge deck [110]. Also, it is evident that now-a-days, the composite sections using Steel encased with Concrete are economic, cost and time effective solution in major civil structures such as bridges and high rise buildings. The fact that each material is used to the fullest advantage makes composite Steel-Concrete construction very efficient and economical [11-20]. However, the real attraction of such construction is based on having an efficient connection of the Steel to the. Concrete and it is this connection that allows transfer of forces and gives composite members their unique behavior. Steel takes the tensile forces whereas concrete take care of the compressive forces.

a) Failure based on longitudinal force.

b) Longitudinal force arrest by embossment.

c) Load must be equally transfer- the concrete helps to attain this function.

d) In past many researchers use normal mix, light weight.

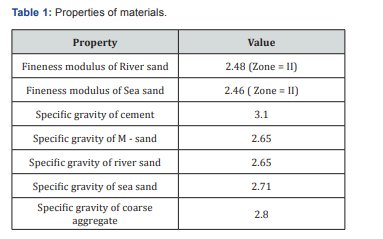

e) Here also we use normal mix but the sand is sea sand (Table 1).

Method to Remove Salt

To remove salts from sea sand, after dry during batching of concrete,

a) Primary Treatment by Water Wash.

b) Secondary Treatment by Alkaline Solution (NaOH).

2H2O + 2Cl2 → 4HCl + O2

HCl + NaOH → Nacl i +H2O

Partially (25%) use treated sea sand with river sand (50%) & M-sand (25%).

FTIR Results

Fourier Transform Infrared Microscopy (FTIR) shows that, the presence of the chloride content has been gradually reduced after water wash. The result of the sea sand before and after washing (Figures 1 & 2).

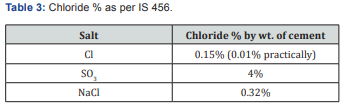

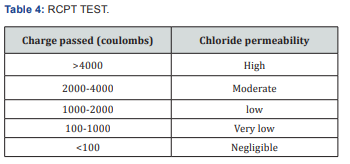

Suitability of Sea Sand as Fine Aggregate for Conc-Rete Production

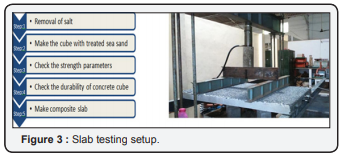

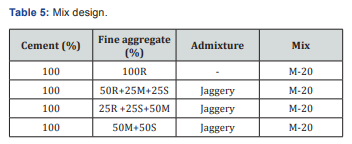

Testing for Chloride Perme-Ability of Concrete: The test configuration and loading procedure were according to recommendation of the IS code. All slabs were simply supported and tested with two symmetrically placed line loads (Figure 3). Single hydraulic jack was used to apply load, which was distributed to the slab through a spreader beam system, which resulted in two line loads being applied to the specimen (Tables 2-4). It took approximately three days from the start of testing to failure of the last slab. Dial gauges were used to measure deflection and end-slip. Deflection at the mid-span was registered for one point [21-30]. The end-slip between the steel sheet and the concrete slab was measured at single ends of the slab. The deflections and end-slip were recorded at each loading increment. The loading of all slabs was of static loading. Testing started with static loading applied by the hydraulic jack to the spreader beams, and transmitted to the slab as a two concentrated line loads across the slab width at a distance of span/4 from each support which is equivalent to the uniformly distributed load case [31-40]. The load was increased gradually in small increments (2.5 KN), and all the loads and displacement readings were taken at each increment (Table 5); (Figure 4).

Where R=River Sand, M=M Sand, S=Sea Sand.

Important Information

a) Specific gravity of fine aggregate: 2.6-2.8.

b) Due to high chloride content water evaporation takes place in concrete cube.

c) Durability check: acid resistance & sulphate resistance & corrosion rate (half-cell potential meter).

d) Calcium nitrate consist admixtures gives more dense for sea sand concrete.

e) Pressure & chemical wash only give 100% removal of chlorides.

Conclusion

The standard journals related to the steel concrete composite slab are studied successfully. The preliminary works like specific gravity, fineness modulus of various construction materials as well as sea sand are worked out successfully [41-50]. In order to find out the type of bonding in washed & unwashed sea sand the FTIR experiment is carried out successfully.

To know more about Juniper Publishers please click on: https://juniperpublishers.com/manuscript-guidelines.php

For more articles in Open Access Journal of Environmental Sciences & Natural Resources please click on: https://juniperpublishers.com/ijesnr/index.php

Comments

Post a Comment