Bioenergy Production from Wastes by Microalgae as Sustainable Approach for Waste Management and to Reduce Resources Depletion - Juniper Publishers

Juniper Publishers-Open Access Journal of Environmental Sciences & Natural Resources

Bioenergy Production from Wastes by Microalgae as Sustainable Approach for Waste Management and to Reduce Resources Depletion

Authored by Sibi G

Abstract

Immense increase in world population leads to endeavour the alternate energy sources and renewable sources have shown high potential in the production of biofuels. Bioenergy is a promising, sustainable source to combat the rising environmental, economic, and technological issues related to depleting fossil fuels. Algae are the most attractive feedstock for bioenergy than terrestrial crops and are well adapted to all ecosystems. Conversion of wastes to energy helps in resource conservation and environmental safety. Bioenergy production using wastewater, effluents, food and agricultural wastes as growth substrates for microalgal cultivation for both biomass and lipid production is one of the sustainable approach. This review presents the biomass and lipid production by microalgae cultivated in various wastes for effective waste management and to reduce the depletion of fossil fuel resources.

Introduction

Increasing global energy demand and depleting fossil fuel resources is an increasing concern worldwide. Resources and energy from wastes has increased significantly in the recent for reducing fossil fuel consumptions and resources depletion. Conversion of wastes to energy helps in resource conservation and environmental safety on a sustainable basis. Production of bioenergy using sustainable sources has been studied extensively due to diminishing fossil fuel reserves. Organic wastes are ideal and inexpensive substrates for microbial oil production by oleaginous microorganisms. Microalgae are regarded as the most promising feedstocks for biofuel production due to the advantages of higher oil content, higher rate of photosynthesis, no direct competition for agricultural land and easy cultivation. Use of organic wastes and wastewater as substrate for microalgae cultivation has potentials to produce microbial oils and to reduce nutrient concentrations in wastes. This review presents the biomass and lipid production by microalgae cultivated in various wastewater, food wastes and agricultural wastes for effective waste management and to reduce the depletion of fossil fuel resources.

Waste Water

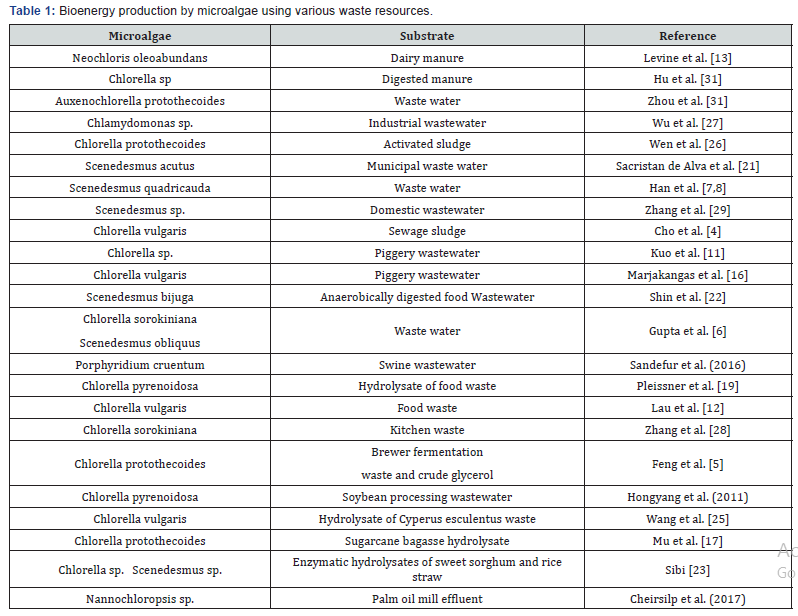

Wastewater contains large number of nutrients and using microalgae to consume the nutrients in conjunction with waste water treatment is economically sustainable. Wastewater could be utilized to large scale microalgae-based biofuel production which substantially reduces the nutrient expenses and eater resources [1,2]. Wastewater including municipal wastewater, domestic wastewater, urban wastewater and digested animal manure effluents are used to cultivate microalgae for biomass and biofuel production. In a study by Wu involving industrial waste water, Chlamydomonas sp.TAI-2 has removed ammonium, nitrate and phosphorous with the lipid content of 18.4% [3]. The better lipid accumulation properties (27.36 and 27.27%) of Scenedesmus quadricauda SDEC-13 cultivated in waste water [4]. FAME analysis exhibited palmitic acid as the predominant constituent followed by oleic acid as second major component. The results indicated the use of sewage water as better substrate for biodiesel production than the chemical medium. In another study, Scenedesmus acutus cultivated in municipal waste water discharges resulted with biomass productivity and lipid accumulation of 79.9 mg L-1 and 282 mg L-1 respectively [5]. Investigations on Chlorella sorokiniana and Scenedesmus obliquus for nutrient removal and lipid production using sewage water was studied by Gupta [6]. S. obliquus demonstrated better lipid accumulation (23.26 % w/w) than C. sorokiniana (22.74% w/v) thereby highlighting the algal species selection for wastewater treatment and lipid production. Integrating algae based biodiesel production with wastewater treatment using Auxenochlorella protothecoides UMN280 [7]. The results of batch cultivation showed high biomass (269 mg L-1 d-1) and lipid (78 mg L-1 d-1) productivity. FAME analysis showed that lipids were mainly composed of C16/C18 fatty acids, which are suitable for biodiesel production. An increase in triacylglycerol production by Scenedesmus sp with increasing cultivation period using domestic wastewater was reported [8]. The lipid production was increased from 32 mg L-1 (21 days) to 148 mg L-1 (45 days) in primary effluent. The capability of Chlorella sp utilizing meat processing water with biomass yield of 0.675-1.538 g L-1 [9] (Table 1).

Demonstrated nutrients in anaerobically digested activated sludge effluent can be remediated through assimilation into algal biomass with 2.43 g L-1 biomass concentration and 29.76% lipid content [10]. Heterotro-1phic cultivation of C. protothecoides using digested chicken manure filtrate yielded total lipid of 5.28 g L-1 [11]. In another study, Chlorella sp was cultivated in piggery wastewater for a period of 10 days batch culture and resulted in 0.839 d-1and 0.681 g L-1 d-1 of specific growth rate and biomass productivity. The highest lipid content and lipid productivity were 29.3% and 0.155 g L-1 d-1 at 25% wastewater, respectively [12]. Hydrolysate obtained from ultrasonic pre-treatment of wasted activated sludge was used as an alternative carbon source for cultivation of Chlorella protothecoides. The lipid content of the culture was 21.5 % with biomass yield of 0.5 g L-1 [13] indicating the use of activated sludge. Use of volatile fatty acids produced from sewage sludge fermentation system as carbon source for cultivation of Chlorella vulgaris was investigated [14]. The cultivation resulted in biomass productivity of 433 ± 11.9 mg L-1 d-1 and lipid contents ranging from 12.87 - 20.01%.

Waste substrate from brewer fermentation and crude glycerol were used as carbon and nitrogen source for the cultivation of C. protothecoides [15]. The lipid productivity of microalgae was compared with the basal medium and was observed higher in the waste substrate medium highlighting the alternative substrates for biofuel production. In a study by Hongyang, C. pyrenoidosa attained biomass productivity of 0.64 g L-1 d-1 and lipid productivity of 0.40 g L-1 d-1 when cultivated in soybean processing waste water [16]. Neochloris oleoabudans grown in anaerobically digested dairy manure yielded 10-30% fatty acid methyl esters on dry with basis [17]. Hu reported that Chlorella sp. grown on acidogenically digested manure could be used as a feedstock for high-quality biodiesel production [18]. Marjakangas has examined the suitability of piggery wastewater as a nutrient source for production of lipid from C. vulgaris [19]. At diluted concentrations of wastewater, the biomass production decreased, and lipid content was increased. The highest lipid content and lipid productivity of 54.7 wt% and 100.7 mg L-1 d-1 was obtained with 20× and 5× dilution respectively. Immobilized cells of Nannochloropsis sp grown in secondary effluent of palm oil mill produced biomass and lipid production of 1.3 g L-1 and 0.356 g L-1, respectively. The repeated-batch cultivation improved the biomass and lipid production and the scale up in 3 L-fluidized bed photobioreactor gave the maximum biomass of 3.28 g L-1 and lipid production of 0.36 g L-1 [20].

Food Waste

Food waste generated from vegetables, fruits, cereals, meat mainly consists of carbohydrates, proteins, lipids, and traces of inorganic compounds. The carbon footprint of food waste is estimated to contribute to the greenhouse gas emissions by accumulating approximately 3.3 billion tonnes of CO2 into the atmosphere per year. Incineration of food waste reduces hinders the recovery of nutrients and valuable chemical compounds thus reducing the economic value of the substrate and may cause severe health and environmental issues. Utilization of food waste as nutrient source for cultivating microorganisms offers to recycle organic matters and production of microbial value-added products. However, food wastes require a pretreatment step to recover low molecular weight nutrients, which the microalgae can easily assimilate.

Food waste hydrolysate was used as culture medium for Schizochytrium mangrovei and Chlorella pyrenoidosa in which 10-20 g microalgal biomass were produced [21]. Enzymatic hydrolysates of food waste were used for the cultivation of Chlorella pyrenoidosa by Plesissner [22]. Under nutrient sufficient batch culture, the cells of C. vulgaris contained 103.8 mg g-1 lipids whereas it was three times higher in biomass cultured under phosphate/nitrogen limited conditions. The conversion of nutrients derived from food waste by C. vulgaris with production of 200 mg g-1 lipids makes microalgae for recycling of food waste and fuel production [23]. Scenedesmus bijuga cultivated in food wastewater effluent has produced lipid content in the range of 13.81 – 15.59 mg L-1d-1 which is higher than the cells grown in synthetic medium [24]. Similarly, biomass productivity was higher (39.4 – 50.75 mg L-1d-1) in the microalgae when cultivated in diluted food wastewater effluent. Recent studies by Zhang demonstrated that anaerobically digested effluent from kitchen waste is a potential medium for cultivation of Chlorella sorokiniana and Scenedesmus sp with the optimal biomass productions of 0.42 g L-1 and 0.55 g L-1 [25]. When compared to the BG 11 medium, the lipid contents of C. sorokiniana and Scenedesmus grown in kitchen waste effluent were in the range of 30.27-41.69% and 35.97-47.39% respectively [26].

Agricultural Waste

Agricultural wastes can be utilized as a substrate for the cultivation of microalga due to their carbon and nitrogen content. Hydrolysates of sugarcane bagasse was used as a carbon source for the cultivation of Chlorella sp [27] and resulted in biomass concentration and lipid content of 5.8 g L-1 and 34.0% respectively. Enzymatic hydrolysates of sweet sorghum and rice straw were used for heterotrophic cultivation of Chlorella vulgaris and Scenedesmus obliquus. Maximum biomass was achieved in combined hydrolysates medium in C. vulgaris (4.8 g L-1) followed by S. obliquus (4.3 g L-1). Total lipid content of Chlorella was ranged from 11.26-29.36 and 15.43-27.24% in Scenedesmus. The qualitative analysis of fatty acids showed very high values of stearic acid (28.41 and 31.01%) and palmitic acid (23.54 and 26.21%) in both microalgae [28]. Hydrolysate of oil crop biomass residues was used to cultivate the microalgae to accumulate higher lipids [29]. Cyperus esculentus waste was used as the carbon source for C. vulgaris [30]. Fed-batch culture has produced maximum biomass, lipid content and lipid productivity of 20.75 g L-1, 36.52%, and 621.53 mg L-1 d-1 respectively [31].

Conclusion

Energy security, rising oil prices and economic objectives are stimulating a strong interest in the development of bioenergy. Biofuel production from microalgae using various waste water, food and agricultural wastes is economically feasible and sustainable approach. Chlorella sp was reported to grow in wide range of waste water and organic wastes for the production of biomass and lipid. However, considering the complexity and nutrient variations among different wastes, there is a need to conduct productivity and techno-economic analysis for the sustainable bioenergy production using microalgae on a larger scale.

To know more about Juniper Publishers please click on: https://juniperpublishers.com/manuscript-guidelines.php

For more articles in Open Access Journal of Environmental Sciences & Natural Resources please click on: https://juniperpublishers.com/ijesnr/index.php

Comments

Post a Comment